Six Sigma is a powerful methodology that helps organizations achieve near-perfect quality in their products, services, and processes. Originating at Motorola in the 1980s, Six Sigma has become a global standard adopted by leading companies like General Electric, Toyota, and Amazon across diverse sectors, including manufacturing, healthcare, finance, and service industries. Its core objective is to minimize defects and variations, ultimately boosting customer satisfaction, reducing costs, and driving profitability. This comprehensive guide delves into the intricacies of Six Sigma, exploring its principles, methodologies, tools, and career opportunities.

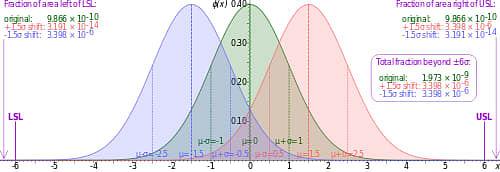

graph of the normal distribution curve in six sigma

graph of the normal distribution curve in six sigma

Credit: Cmglee, via Wiki Creative Commons CC BY-SA 3.0

Understanding Six Sigma

At its core, Six Sigma is a statistical measure of how close a process is to perfection. A Six Sigma process boasts a remarkably low defect rate of only 3.4 defects per million opportunities. This level of precision is achieved through rigorous data analysis, statistical methods, and a structured approach to process improvement. Six Sigma methodologies provide a framework for identifying and eliminating the root causes of variation, leading to more predictable and consistent outcomes.

The Core Principles of Six Sigma

Five fundamental principles underpin the Six Sigma methodology:

1. Customer Focus

Six Sigma prioritizes understanding and meeting customer needs. By defining quality from the customer’s perspective, organizations can ensure that their efforts align with what truly matters to their target audience. This customer-centric approach drives improvements that enhance satisfaction and build loyalty.

2. Data-Driven Approach

Six Sigma relies heavily on data analysis and statistical methods to identify areas for improvement. By meticulously measuring and analyzing processes, organizations can pinpoint the root causes of defects and variations. This data-driven approach ensures that decisions are based on objective evidence, leading to more effective and sustainable improvements.

3. Process Focus

Six Sigma emphasizes improving entire processes, not just individual tasks. By analyzing the flow of work and identifying bottlenecks or inefficiencies, organizations can optimize their operations for maximum efficiency and quality. This holistic approach ensures that improvements are systemic and sustainable.

4. Proactive Management

Six Sigma encourages proactive measures to prevent defects rather than simply reacting to them. By identifying potential problems before they occur, organizations can avoid costly rework and maintain consistent quality. This proactive approach minimizes disruptions and enhances overall efficiency.

5. Collaboration and Teamwork

Six Sigma fosters collaboration and teamwork across different departments and levels within an organization. By involving all stakeholders in the improvement process, organizations can leverage diverse perspectives and expertise. This collaborative approach ensures buy-in and promotes a shared commitment to quality.

The DMAIC Methodology

The most widely used Six Sigma methodology is DMAIC, a five-phase process for improving existing processes:

1. Define

This phase focuses on clearly defining the problem, project goals, and customer requirements. It involves gathering information, mapping the process, and establishing clear metrics for success.

2. Measure

This phase involves collecting data to measure the current performance of the process. It includes selecting appropriate metrics, establishing data collection methods, and analyzing the data to understand the extent of the problem.

3. Analyze

This phase aims to identify the root causes of the problem. It involves using various analytical tools and techniques to explore the data and determine the factors contributing to defects and variations.

4. Improve

This phase focuses on developing and implementing solutions to address the root causes identified in the analysis phase. It involves testing and validating the solutions to ensure they effectively improve the process.

5. Control

This phase involves implementing controls to sustain the improvements and prevent the problem from recurring. It includes documenting the changes, establishing monitoring procedures, and training employees on the new processes.

The DMADV Methodology

DMADV, also known as Design for Six Sigma (DFSS), is used for designing new processes or products:

1. Define

Similar to DMAIC, this phase involves defining the project goals and customer requirements.

2. Measure

This phase focuses on measuring customer needs and specifications.

3. Analyze

This phase involves analyzing design alternatives and selecting the best option.

4. Design

This phase focuses on developing the detailed design of the new process or product.

5. Verify

This phase involves verifying the design through pilot testing and validation.

Six Sigma Tools and Techniques

Six Sigma employs a variety of tools and techniques, including:

- Statistical Process Control (SPC): Used to monitor and control process variation.

- Failure Mode and Effects Analysis (FMEA): Identifies potential failures and their impact.

- Design of Experiments (DOE): Determines the relationship between factors and their effects.

- Regression Analysis: Analyzes the relationship between variables.

- Value Stream Mapping: Visualizes the flow of materials and information.

- 5S Methodology: Organizes the workplace for efficiency and safety.

Six Sigma Certification Levels

Several levels of Six Sigma certification exist, each requiring different levels of knowledge and experience:

- White Belt: Basic understanding of Six Sigma principles.

- Yellow Belt: Participates in projects and understands DMAIC.

- Green Belt: Leads Green Belt projects and assists Black Belts.

- Black Belt: Leads Six Sigma projects and trains Green Belts.

- Master Black Belt: Mentors Black Belts and leads organizational initiatives.

Six Sigma Career Opportunities

Six Sigma certification can open doors to various career paths, including:

- Six Sigma Consultant: Advises organizations on process improvement.

- Six Sigma Project Manager: Manages Six Sigma projects.

- Six Sigma Black Belt: Leads Six Sigma projects and teams.

- Six Sigma Master Black Belt: Oversees organizational Six Sigma initiatives.

- Quality Manager: Ensures products and services meet quality standards.

Conclusion

Six Sigma is a valuable methodology for organizations seeking to achieve operational excellence and improve customer satisfaction. By embracing its principles, methodologies, and tools, businesses can drive significant improvements in quality, efficiency, and profitability. Whether you’re an individual looking to enhance your career prospects or an organization aiming to transform its operations, Six Sigma offers a powerful framework for achieving success.

FAQs

1. What is the key benefit of Six Sigma?

The key benefit of Six Sigma is its focus on reducing defects and variations, leading to improved quality, reduced costs, and increased customer satisfaction.

2. How does DMAIC differ from DMADV?

DMAIC is used for improving existing processes, while DMADV is used for designing new processes or products.

3. What is the highest level of Six Sigma certification?

Master Black Belt is the highest level of Six Sigma certification.

4. What industries use Six Sigma?

Six Sigma is used across various industries, including manufacturing, healthcare, finance, and service industries.

5. How can I get Six Sigma certified?

You can get Six Sigma certified by completing a training program and passing a certification exam. Several organizations offer Six Sigma certification, including the American Society for Quality (ASQ) and the International Association for Six Sigma Certification (IASSC).