The manufacturing industry generates a massive amount of data, encompassing everything from the number of units produced to intricate performance metrics. However, raw data alone holds limited value. To thrive in today’s competitive landscape, manufacturers must transform this data into actionable insights. This is where Production KPIs, visualized through dashboards and reports, become indispensable tools for driving efficiency, profitability, and growth. By effectively leveraging these tools, manufacturers can gain a comprehensive understanding of their operations, identify areas for improvement, and ultimately optimize their entire production process.

KPI meaning finance and KPI meaning in food industry provide frameworks for selecting and tracking key performance indicators. These frameworks are applicable across various industries, including manufacturing. Applying these frameworks allows manufacturers to tailor KPI selection to the specifics of their production processes, ensuring alignment with overall business objectives.

Let’s delve into the world of Production KPIs and explore how they can revolutionize your manufacturing operations.

The Power of Production KPI Dashboards and Reports

While most production assets have some form of reporting, it’s often fragmented and isolated from other crucial data. This makes it difficult to form a holistic view of performance and extract meaningful insights. The advantage of dedicated Production KPI dashboards and reports lies in their ability to consolidate data from various sources and present it in a visually compelling and easily digestible format. Graphs, charts, and other visualizations transform complex data into clear narratives, enabling stakeholders at all levels to quickly grasp key performance trends and identify areas requiring attention.

These dashboards serve a dual purpose. For management, they provide invaluable information for strategic decision-making and performance improvement initiatives. For production operators, real-time dashboards offer immediate visibility into the manufacturing process, allowing for proactive adjustments and optimizations.

A Production KPIs report overalyed on a dashboard with charts

A Production KPIs report overalyed on a dashboard with charts

21 Essential Production KPIs to Track

From overall equipment effectiveness (OEE) to customer rejects and on-time delivery, a wide range of Production KPIs can provide valuable insights into different aspects of the manufacturing process. By carefully selecting and tracking the right KPIs, manufacturers can gain a comprehensive understanding of their strengths and weaknesses, identify bottlenecks, and drive continuous improvement.

Key Performance Indicators for Efficiency

- Overall Equipment Effectiveness (OEE): A comprehensive metric that measures the percentage of planned production time that is truly productive. OEE considers availability, performance, and quality to provide a holistic view of equipment effectiveness.

- Cycle Time: The time it takes to complete one production cycle, from start to finish. Reducing cycle time can significantly improve output and efficiency.

- Throughput: The number of units produced within a specific timeframe. Monitoring throughput helps identify potential bottlenecks and optimize production flow.

- Capacity Utilization: The percentage of total production capacity that is being utilized. Maximizing capacity utilization is crucial for optimizing resource allocation and minimizing downtime.

Quality-Focused Production KPIs

- Defect Rate: The percentage of units produced that are defective. Tracking defect rates helps identify quality issues and implement corrective actions.

- First Pass Yield: The percentage of units that pass quality inspection on the first attempt. This KPI highlights the effectiveness of quality control measures early in the production process.

- Customer Rejects: The number of units rejected by customers due to quality issues. Monitoring customer rejects provides valuable feedback on product quality and customer satisfaction.

- Scrap Rate: The percentage of raw materials that are discarded as waste during the production process. Minimizing scrap rates is essential for reducing costs and improving sustainability.

KPIs for Delivery and Customer Satisfaction

- On-Time Delivery: The percentage of orders delivered to customers on or before the promised delivery date. Maintaining high on-time delivery rates is crucial for customer satisfaction and retention.

- Order Fulfillment Cycle Time: The time it takes to complete an order, from order placement to delivery. Optimizing this cycle time can improve customer experience and reduce lead times.

- Customer Lead Time: The time elapsed between a customer placing an order and receiving the finished product.

Cost-Related Production KPIs

- Production Cost per Unit: The total cost of producing one unit, including labor, materials, and overhead. Tracking this KPI helps identify cost-saving opportunities and improve profitability.

- Inventory Turnover: The rate at which inventory is sold and replaced. Optimizing inventory turnover minimizes storage costs and reduces the risk of obsolescence.

- Maintenance Costs: The total cost of maintaining equipment and machinery. Effective maintenance strategies can minimize downtime and extend the lifespan of assets.

Safety and Compliance KPIs

- Lost Time Injury Frequency Rate (LTIFR): A measure of the number of lost-time injuries per a specified number of working hours. Prioritizing safety and minimizing LTIFR is essential for creating a safe and productive work environment.

- Environmental Compliance: Measuring adherence to environmental regulations and standards. This KPI reflects a company’s commitment to sustainability and responsible manufacturing practices.

KPI meaning finance provides guidance on selecting KPIs that are directly linked to financial performance, while KPI meaning in food industry offers insights into specific KPIs relevant to food manufacturing processes. By integrating these frameworks, manufacturers can create a comprehensive and effective KPI strategy.

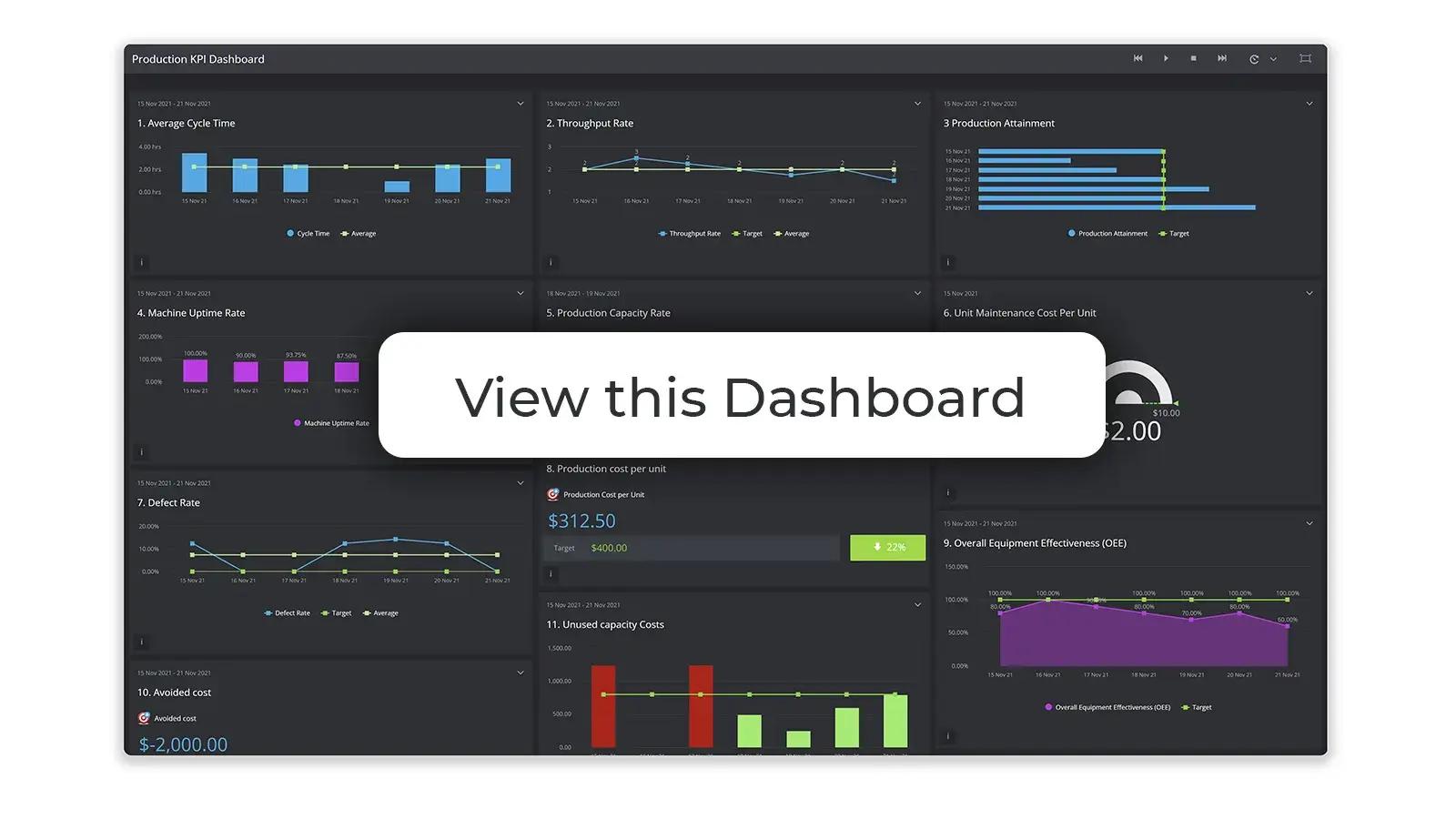

A screenshot of a Production KPI dashboard with 12 different charts showing various Production KPIs, with the words view this dashboard written in bold text

A screenshot of a Production KPI dashboard with 12 different charts showing various Production KPIs, with the words view this dashboard written in bold text

Implementing Production KPI Dashboards and Reports

Choosing the right software solution is paramount for effectively implementing Production KPI dashboards and reports. Look for a platform that offers:

- Data Integration: Seamlessly integrates with various data sources, including ERP systems, MES, and SCADA.

- Customization: Allows for the creation of customized dashboards and reports tailored to specific business needs.

- Real-time Monitoring: Provides real-time visibility into key performance indicators, enabling proactive adjustments.

- Alerting and Notifications: Sets up automated alerts and notifications to flag critical issues and deviations from targets.

- Collaboration and Sharing: Facilitates collaboration and sharing of dashboards and reports across teams and departments.

Conclusion: Driving Manufacturing Excellence Through Data-Driven Insights

In today’s data-driven world, Production KPIs are no longer a luxury but a necessity for manufacturers seeking to optimize their operations and achieve sustainable growth. By leveraging the power of KPI dashboards and reports, manufacturers can transform raw data into actionable insights, identify areas for improvement, and drive continuous improvement across their entire production process. Embrace the power of data and unlock the full potential of your manufacturing operations.

FAQs

Q: What are the benefits of using Production KPI dashboards?

A: Production KPI dashboards provide real-time visibility into key performance metrics, enabling proactive decision-making and optimization of the manufacturing process. They also facilitate communication and collaboration across teams.

Q: How do I choose the right Production KPIs for my business?

A: The selection of KPIs should align with your specific business objectives and industry. Consider factors such as efficiency, quality, delivery, cost, and safety.

Q: What is the role of real-time data in Production KPI monitoring?

A: Real-time data allows for immediate identification of issues and deviations from targets, enabling prompt corrective actions and minimizing downtime.

We encourage you to share your questions and experiences with Production KPIs in the comments below. Let’s collaborate and learn from each other to drive manufacturing excellence through data-driven insights.