📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download

Six Sigma is a powerful methodology that helps organizations achieve near-perfect quality in their products, services, and processes. Initially developed by Motorola in the 1980s, Six Sigma has become a globally recognized approach adopted by leading companies like General Electric, Toyota, and Amazon. This data-driven approach focuses on minimizing defects and variations, ultimately leading to improved customer satisfaction, reduced costs, and increased profits. This comprehensive guide delves into the principles, methodologies, tools, and career opportunities associated with Six Sigma.

Understanding Six Sigma

Six Sigma aims to achieve a defect rate of just 3.4 defects per million opportunities. This impressive level of quality is attained through a structured, data-driven approach called DMAIC (Define, Measure, Analyze, Improve, Control). This cyclical process allows for continuous improvement and refinement. The term “Six Sigma” itself comes from the Greek letter sigma (σ), representing standard deviation in statistics. A six sigma process indicates that the mean is six standard deviations away from the nearest specification limit, signifying an exceptionally low defect rate.

graph of the normal distribution curve in six sigma

graph of the normal distribution curve in six sigma

Credit: Cmglee, via Wiki Creative Commons CC BY-SA 3.0

Lean Six Sigma: A Synergistic Approach

Lean Six Sigma combines the principles of Lean manufacturing with the statistical rigor of Six Sigma. Lean focuses on eliminating waste and maximizing efficiency by streamlining processes and optimizing resource utilization. Six Sigma, on the other hand, employs statistical methods to reduce variation and defects. The synergy of these two methodologies provides a holistic approach to process improvement, applicable across various industries.

The Five Key Principles of Six Sigma

Six Sigma is grounded in five core principles that guide its implementation:

Customer Focus: Prioritizing customer needs and understanding their expectations is paramount. This involves defining quality standards based on customer requirements and striving to exceed them.

Data-Driven Analysis: Decisions are based on data and statistical analysis, ensuring objectivity and accuracy in identifying areas for improvement. This includes rigorous data collection and analysis to pinpoint the root causes of defects.

Process Improvement: Continuously identifying and eliminating defects and variations in processes is crucial. This involves streamlining workflows, optimizing resource allocation, and implementing robust quality control measures.

five key principles of six sigma

five key principles of six sigma

Collaboration and Teamwork: Effective implementation requires cross-functional collaboration and teamwork. Engaging stakeholders across different departments ensures buy-in and facilitates the smooth implementation of process changes.

Flexibility and Adaptability: Six Sigma emphasizes a culture of flexibility and responsiveness to change. Organizations must be adaptable to new processes and procedures to maximize the benefits of Six Sigma implementation.

Six Sigma Methodologies: DMAIC and DMADV

Two primary methodologies drive Six Sigma initiatives: DMAIC and DMADV.

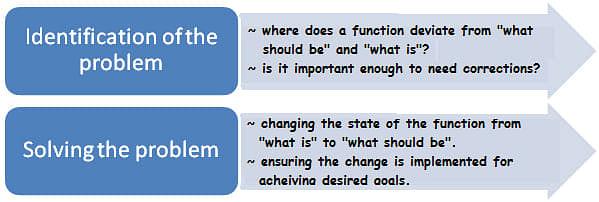

DMAIC (Define, Measure, Analyze, Improve, Control): This methodology focuses on improving existing processes. It involves defining the problem, measuring key metrics, analyzing data to identify root causes, implementing improvements, and establishing control mechanisms to sustain gains.

DMADV (Define, Measure, Analyze, Design, Verify): This methodology is used for designing new processes or significantly redesigning existing ones. It involves defining project goals, measuring critical-to-quality (CTQ) characteristics, analyzing data to understand design requirements, designing the new process, and verifying its effectiveness.

The DMAIC Process in Detail

The DMAIC process is a five-phase cycle that systematically addresses process improvement:

Define: Clearly define the problem, project goals, and customer requirements. This phase sets the scope and objectives for the entire project.

Measure: Collect data and measure key performance indicators (KPIs) to establish a baseline for improvement. This involves identifying the appropriate metrics and data collection methods.

Analyze: Analyze the collected data to identify the root causes of defects and variations. This phase involves using statistical tools and techniques to pinpoint the underlying issues driving the problem.

Improve: Develop and implement solutions to address the root causes identified in the analysis phase. This involves designing and testing process improvements to ensure effectiveness.

Control: Establish control mechanisms to monitor the implemented improvements and ensure sustained gains. This phase involves developing monitoring plans and procedures to prevent regression to previous performance levels.

📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download

Six Sigma Techniques and Tools

Six Sigma utilizes a variety of techniques and tools to analyze processes and identify areas for improvement. Some key techniques include:

- Brainstorming: Generating ideas and solutions through collaborative group discussions.

- Root Cause Analysis (5 Whys): Repeatedly asking “why” to uncover the underlying cause of a problem.

- Voice of the Customer (VOC): Gathering and analyzing customer feedback to understand their needs and expectations.

- 5S System: A workplace organization methodology focusing on Sort, Set in Order, Shine, Standardize, and Sustain.

- Kaizen (Continuous Improvement): A philosophy of ongoing incremental improvements.

- Benchmarking: Comparing performance against industry best practices.

- Poka-Yoke (Mistake Proofing): Designing processes to prevent errors.

- Value Stream Mapping: Visualizing the flow of materials and information to identify waste.

Six Sigma also employs a range of statistical tools, including:

- Cause and Effect Analysis: Identifying potential causes of a problem.

- Flow Chart: Visualizing the steps in a process.

- Pareto Chart: Identifying the most significant factors contributing to a problem.

- Histogram: Displaying the distribution of data.

- Check Sheet: Collecting data in a structured format.

- Scatter Plot: Analyzing the relationship between two variables.

- Control Chart: Monitoring process performance over time.

Key Six Sigma Techniques in use

Key Six Sigma Techniques in use

Fig: Key Six Sigma Techniques in Use

Six Sigma Certification Levels

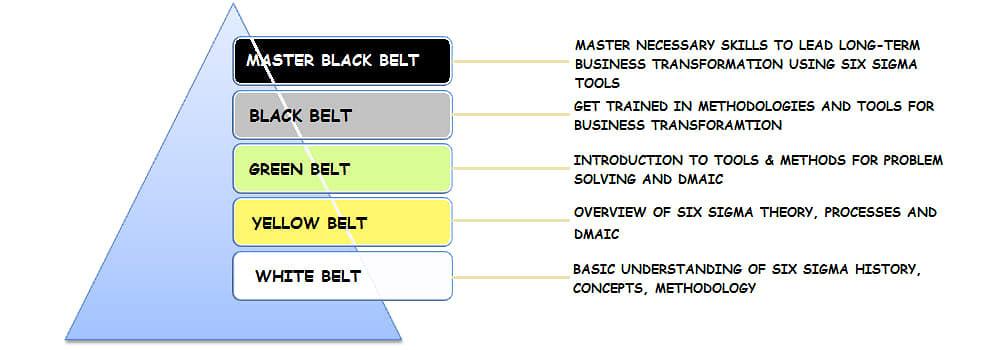

Six Sigma certifications are structured in a hierarchical system, reflecting different levels of expertise and responsibility:

- White Belt: Introductory level, providing basic knowledge of Six Sigma concepts.

- Yellow Belt: Participates in projects and reviews process improvements.

- Green Belt: Leads Green Belt projects and assists Black Belts in data collection and analysis.

- Black Belt: Leads Six Sigma projects, trains team members, and ensures sustained improvements.

- Master Black Belt: Leads organizational Six Sigma initiatives, coaches Black Belts and Green Belts, and drives business transformation.

The five-tiered levels of Six Sigma Certification

The five-tiered levels of Six Sigma Certification

Fig: The five-tiered levels of Six Sigma Certification

Six Sigma Career Paths and Salary Expectations

Six Sigma offers a variety of career paths with attractive salary prospects:

- Six Sigma Consultant: Advises organizations on process improvements.

- Six Sigma Project Manager: Oversees Six Sigma projects.

- Six Sigma Black Belt: Leads Six Sigma projects and trains team members.

- Six Sigma Master Black Belt: Leads organizational Six Sigma initiatives.

- Quality Manager: Ensures products/services meet quality standards.

Salaries for Six Sigma professionals can range from $90,000 to $140,000 per year, depending on the certification level and experience.

Conclusion

Six Sigma provides a robust framework for achieving operational excellence and driving business transformation. By embracing its principles, methodologies, and tools, organizations can significantly improve their processes, reduce costs, enhance customer satisfaction, and gain a competitive edge in the marketplace. With the growing demand for Six Sigma professionals, pursuing certification can open up exciting career opportunities with attractive salary prospects.

FAQs

1. What are the key benefits of implementing Six Sigma?

Six Sigma can lead to reduced defects, improved quality, increased efficiency, lower costs, enhanced customer satisfaction, and increased profitability.

2. What are the main differences between DMAIC and DMADV?

DMAIC is used for improving existing processes, while DMADV is used for designing new processes or significantly redesigning existing ones.

3. What are some common tools used in Six Sigma?

Common tools include brainstorming, root cause analysis, 5 Whys, Voice of the Customer, 5S System, Kaizen, benchmarking, Poka-Yoke, and Value Stream Mapping, along with various statistical tools.

4. What are the different Six Sigma certification levels?

The levels are White Belt, Yellow Belt, Green Belt, Black Belt, and Master Black Belt, each representing increasing levels of expertise and responsibility.

5. What are some typical career paths for Six Sigma professionals?

Typical career paths include Six Sigma Consultant, Six Sigma Project Manager, Six Sigma Black Belt, Six Sigma Master Black Belt, and Quality Manager.

6. How can I get started with learning Six Sigma?

Numerous online and offline resources, including training courses and certification programs, are available to learn Six Sigma.

7. What is the significance of the term “Six Sigma”?

The term refers to a statistical measure indicating a very low defect rate of 3.4 defects per million opportunities.

8. How does Lean Six Sigma differ from traditional Six Sigma?

Lean Six Sigma integrates the principles of Lean manufacturing, focusing on waste elimination, with the statistical rigor of Six Sigma.

9. What are some industries that commonly use Six Sigma?

Six Sigma is widely used in manufacturing, healthcare, finance, IT, and service industries.

10. What are the typical salary expectations for Six Sigma professionals?

Salaries can range from $90,000 to $140,000 per year depending on certification level, experience, and industry.

📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download