📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download

Lean Six Sigma Principles Applied to Project Management

Lean Six Sigma Principles Applied to Project Management

Lean Six Sigma is a powerful methodology that integrates the waste-reduction principles of Lean manufacturing with the process improvement strategies of Six Sigma. While initially developed for manufacturing environments, Lean Six Sigma has demonstrated its versatility and effectiveness across diverse industries, including healthcare, finance, IT, and project management. This comprehensive guide explores the application of Lean Six Sigma principles within project management, demonstrating how it can significantly enhance project efficiency, minimize costs, and elevate the quality of project outcomes.

Understanding Lean Six Sigma Principles

Before examining the practical application of Lean Six Sigma in project management, it’s crucial to understand the core concepts of both Lean and Six Sigma.

Lean Manufacturing: Eliminating Waste

Lean manufacturing centers on eliminating waste, defined as any activity or resource that doesn’t add value to the final product or service from the customer’s perspective. Lean identifies seven primary types of waste, commonly represented by the acronym TIMWOOD: Transportation, Inventory, Motion, Waiting, Overproduction, Over-Processing, and Defects. By systematically addressing these wastes, Lean strives to create streamlined and efficient processes.

Six Sigma: Reducing Variation and Defects

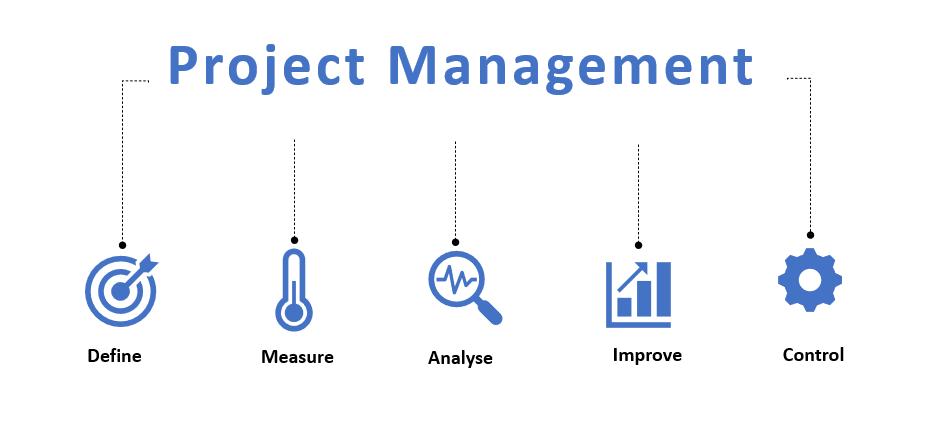

Six Sigma is a data-driven methodology that focuses on improving process quality by identifying and eliminating defects, reducing variability, and striving for near-perfection in process performance. It utilizes the DMAIC cycle (Define, Measure, Analyze, Improve, Control) as a structured framework for problem-solving and process optimization.

Lean Six Sigma: A Synergistic Approach

The integration of Lean and Six Sigma creates a synergistic approach that leverages the strengths of both methodologies. Organizations can achieve faster, more efficient processes while simultaneously improving quality, minimizing errors, and enhancing customer satisfaction.

Lean Six Sigma in Project Management

Project management involves planning, executing, and closing projects to achieve specific goals and meet predefined success criteria. Implementing Lean Six Sigma principles within project management offers several key advantages.

Defining Project Scope with DMAIC

The DMAIC framework provides a structured approach to defining and managing projects effectively.

- Define: Clearly articulate the project’s objectives, scope, deliverables, and stakeholders. This phase ensures alignment with organizational strategic goals and identifies critical success factors.

- Measure: Establish key performance indicators (KPIs) and benchmarks to track progress and measure success. In project management, this involves setting milestones, timelines, and budget constraints.

- Analyze: Identify potential risks, process bottlenecks, and areas of inefficiency. This analysis enables prioritization of tasks and resources to mitigate delays and cost overruns.

- Improve: Implement process improvements and optimize resource allocation. This may involve refining workflows, enhancing communication, or adopting new project management tools and techniques.

- Control: Monitor project progress continuously and implement control mechanisms to ensure the project stays on track. This includes regular status updates, quality checks, and adjustments to the project plan as needed.

Reducing Waste in Project Management

Lean principles help identify and eliminate non-value-added activities in project processes.

- Identifying Waste: Utilizing the TIMWOOD framework helps identify waste in various project activities. Examples include overproduction of documentation, waiting for approvals, and defects requiring rework.

- Value Stream Mapping: This visual tool maps the entire project process flow, highlighting areas where waste occurs and enabling targeted improvements.

- Kanban: Kanban boards visualize work in progress (WIP) and manage task flow, preventing team overload and minimizing multitasking.

Improving Quality through Six Sigma

Six Sigma’s focus on defect reduction significantly enhances project quality.

- Root Cause Analysis: Techniques like the Fishbone Diagram (Ishikawa) and 5 Whys help identify the root causes of project problems and defects, enabling effective solutions and preventing recurrence.

- Control Charts: These charts monitor project performance and identify variations, allowing for timely corrective actions before minor issues escalate into major problems.

- Continuous Improvement: Fostering a culture of continuous improvement encourages feedback and iterative process enhancements, leading to ongoing quality improvements throughout the project lifecycle.

Optimizing Resources and Reducing Costs

Lean Six Sigma enables effective resource utilization and cost reduction.

- Resource Utilization: Analyzing resource allocation with Six Sigma’s statistical tools ensures efficient utilization of time, personnel, and budget.

- Cost Reduction: Eliminating waste and improving process efficiency directly contribute to cost savings.

- Risk Management: Failure Mode and Effects Analysis (FMEA) helps anticipate and mitigate potential risks, minimizing costly delays and failures.

Enhancing Team Collaboration and Communication

Lean Six Sigma promotes effective communication and collaboration within project teams.

📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download

- Standardized Processes: Standardized project management processes ensure consistency and clarity, improving coordination and reducing confusion.

- Visual Management: Dashboards and progress trackers keep all team members informed and aligned.

- Daily Stand-ups: These brief meetings facilitate quick communication, enabling early identification of issues and promoting project momentum.

Case Studies: Lean Six Sigma in Action

Real-world examples demonstrate the practical benefits of Lean Six Sigma in various project settings.

- Healthcare: A hospital streamlined its EHR system implementation using Lean Six Sigma, reducing implementation time by 30% while staying within budget.

- Manufacturing: A manufacturing company applied Lean Six Sigma to a capital project, achieving a 15% cost reduction and timely completion through optimized resource allocation.

- IT: An IT firm minimized post-launch software issues by implementing Six Sigma’s defect reduction techniques, resulting in increased client satisfaction and reduced maintenance costs.

Challenges and Considerations

Implementing Lean Six Sigma requires careful planning and consideration.

- Cultural Resistance: Team members unfamiliar with the methodology may resist change. Training and change management strategies are essential for successful adoption.

- Complexity: Lean Six Sigma tools and techniques require a solid understanding of both methodologies. Adequate training and support are crucial.

- Time and Resources: While Lean Six Sigma delivers long-term benefits, initial investment in training and process analysis is necessary.

Conclusion

Integrating Lean Six Sigma into project management empowers project managers to deliver exceptional results. By combining waste reduction with defect reduction, projects become more efficient, cost-effective, and higher quality. Lean Six Sigma offers a proven framework for optimizing project management practices across diverse industries, contributing to project success and organizational excellence.

FAQ

Q: What are some common misconceptions about Lean Six Sigma in project management?

A: One common misconception is that Lean Six Sigma is only applicable to large-scale projects. In reality, its principles can be adapted to projects of any size. Another misconception is that Lean Six Sigma is overly complex and requires extensive statistical knowledge. While some statistical tools are used, the core principles are straightforward and can be learned by anyone.

Q: How can I get started with implementing Lean Six Sigma in my projects?

A: Start by familiarizing yourself with the core principles of Lean and Six Sigma. Consider taking a basic training course or reading introductory materials. Then, begin by identifying areas of waste and inefficiency in your current project processes. Use the DMAIC cycle to guide your improvement efforts and track your progress.

Q: What are some key resources for learning more about Lean Six Sigma in project management?

A: There are numerous books, articles, and online resources available. Look for resources from reputable organizations such as the American Society for Quality (ASQ) and the Lean Enterprise Institute.

We encourage you to share your own experiences and questions about Lean Six Sigma in project management in the comments below. Let’s build a community of knowledge and continuous improvement!

📚 Unlock the World of AI and Humanity with These Two Free Books! 🚀

Dive into the thrilling realms of artificial intelligence and humanity with "The ECHO Conundrum" and "Awakening: Machines Dream of Being Human". These thought-provoking novels are FREE this week! Don't miss the chance to explore stories that challenge the boundaries of technology and what it means to be human.

Read More & Download